This paper discusses the construction and research of water reuse system in green intelligent buildings to improve the efficiency of water resources utilization and promote the sustainable development of the construction industry, which is of great significance for environmental protection and energy saving. In this paper, the design principles, technical parameters and costs of the water reuse system are considered comprehensively. The social and economic benefits are explored through empirical analysis of water reuse systems in different types of buildings. The COD concentration of treated water in the middle water is reduced to below 50mg/L, and the SS concentration is stabilized between 8\(\mathrm{\sim}\)10mg/L, which is in line with the standard. The actual scale of water production is significant, with an average daily treatment volume of 2548.8816m\(^{3}\) for the university water project, and 628.4478m\(^{3}\) and 431.625m\(^{3}\) for the residential neighborhood and public building, respectively. The average value of the whole life cycle cost prediction is about 39,767,335,000 yuan, and the payback period is 9 years. This study demonstrates the effectiveness and economic feasibility of the water reuse system for green intelligent buildings, which is important for improving water utilization efficiency and environmental sustainability in the construction industry.

Copyright © 2024 You Li and Hui Zhong. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Water system refers to the purification and treatment of water, water collection, water supply, metering, testing facilities and other ancillary facilities combined in a combination of the building or building community is one of the functional supporting facilities [1, 2, 3]. China is a country with water shortages, the contradiction between supply and demand for water resources is particularly prominent. According to the data shows that the national per capita water resources is only equal to 1/4 of the world per capita level, ranking 105th in the world, is listed as one of the 13 water-poor countries in the world. with the improvement of the quality of life of the modern people, the quality of water supply to the building water quality requirements of the standard is also higher and higher, at the same time the country to implement the sustainable use of water resources and protection policies, advocating water conservation [4, 5].

Building water reuse refers to the monolithic building, a local group of buildings or a small regional building district all kinds of drainage water after appropriate treatment, recycling back to the original building as a water supply system for miscellaneous uses. The choice of water source should be based on the water quality, water quantity and drainage conditions and the requirements of water reuse to determine the first choice of those who have sufficient water quality, stable supply, water quality treatment difficulties, low concentration of pollutants, the use of safe and easy to accept the residents of the drainage water as a source of water [6, 7].

China is a country with serious water shortage in general, advocating scientific water use, water conservation, and taking the road of sustainable development of water resources is one of the important measures to solve the contradiction between supply and demand of water, and water conservation is an important assessment index of the green building assessment system. The sustainable utilization of water resources [8, 9, 10].

Water reuse can not only realize the resourcefulness of sewage and wastewater, alleviate the shortage of water resources, but also reduce the discharge of sewage and wastewater, reduce the pollution of the water environment, but also alleviate the phenomenon of overloading of the urban sewers, which has obvious social, environmental and economic benefits [11]. Literature [12] explored the program of grey water treatment of the city, and the dialectical analysis of the existing methods in order to solve the problems of watering of the urban vegetation, water conservation and user interaction, etc. Literature [13] designed a passive rainwater collection system, which can flush the roof and cistern, and based on the analysis of economics, the design can save 8.5 tons of water for each building. Literature [14] developed a strawberry intelligent planting management platform based on the Internet of Things, in order to realize intelligent management of greenhouses, save water resources, and improve the utilization rate of water, and after the feedback of the actual application, it was learned that water utilization rate of greenhouses was increased by 226.1 percent, and water utilization rate was increased by 20 percent. After the feedback of practical application, it was learned that the water utilization rate of greenhouse was increased by 226.1%, and the cost of pesticide was reduced by 32.5%, which brought considerable economic benefits. Literature [15] studied how the green roof (GR) and vertical greening system (VGS) affect the rainwater quality, and this made suggestions on the pollution caused by these greening facilities, such as optimizing the construction methods and materials used in the construction of GR and VGS, etc.

Literature [16] made suggestions on the use of integrated film and water reuse system, and the use of integrated membrane to treat water. The effectiveness of integrated membrane water reuse (IMR) system was investigated and it was found that ARGs, intI1 and 16S rRNA genes were significantly reduced in the IMR system, and that the system could remove multiple antibiotic-resistant bacteria [17]. developed a new analytical framework for investigating water reuse and energy trade-offs based on the life-cycle perspective, which is conducive to the reduction of the energy sector’s impacts on watersheds, as well as the ability of manufacturers to monitor and control the impacts themselves, and to optimize the construction methods and materials used in these green facilities. Literature [18] describes the role of reclaimed water and the water cycle in improving water use and reducing the operational costs associated with water resources in enterprises. Literature [19] uses high-density disinfected municipal wastewater for reclaimed water for agriculture in Italy, while the World Health Organization proposes a pragmatic approach based on a microbial risk assessment in order to explore more rational ways to achieve this. Literature [20] based on big data technology to determine the level of public awareness of reclaimed water reuse, and policy guidance and popularization to improve public acceptance of reclaimed water, which is conducive to environmental protection and improve economic efficiency.

This study focuses on the construction of water reuse system in green intelligent buildings. First, based on the real demand and technical characteristics of water reuse systems, membrane bioreactor (MBR) technology is selected as the core of the study. Then, the system design principles, technical parameters and costs are comprehensively considered, and different types of building water reuse systems are empirically analyzed. By evaluating the social and economic benefits of the system, its performance in practical applications is explored. Ultimately, this study verifies the effectiveness and economic feasibility of water reuse systems in green intelligent buildings through a combination of theoretical and empirical methods, providing a scientific basis and practical guidance for the efficient utilization of water resources and environmental protection in the construction industry.

The core of the green building design concept is to provide a healthy, comfortable and sustainable living and working environment by minimizing negative impacts on the environment. It focuses on the application of energy-saving and emission reduction, resource recycling, and environmentally friendly technologies and materials.

The design is based on factors such as the geographical environment, climatic conditions and local resources in which the building is located. Climatic conditions and resources vary from region to region, so green building design should be appropriately adapted to specific situations. For example, in hot areas proper shading and ventilation measures can be adopted to reduce the use of air conditioning. And in cold areas, good insulation design and solar energy utilization systems can be used to reduce energy consumption for heating. The principle of adapting to local conditions can maximize the use of local resources and improve the energy use efficiency of buildings. Green building design will consider local climatic conditions to optimize the energy consumption and comfort of the building. For example, in hot regions, buildings with north-south orientation can be selected to minimize the impact of solar radiation on the building and to reduce indoor temperature through reasonable shading design. In cold regions, appropriate thermal insulation materials and insulation techniques can be selected to reduce heat loss.

Water reuse technology has a positive significance for urban development, which can effectively promote urban development and maximize the treatment of resources on the basis of meeting people’s water needs in order to improve the efficiency of water resources. However, in the actual application of the technology, there are still some deficiencies, and it is necessary to innovate from multiple perspectives to solve the problems that exist in the technology. For example, at this stage of water reuse technology in the application process, there are still some management problems, there are deficiencies in the design and management, affecting the efficiency and effectiveness of water reuse. The water project by its own factors present obvious particularity, the requirements of the application of the overall maturity of the technology, has a strong economy, in practice, can be easy to manage and control, and improve the stability of the operation, the water quality is good, in line with the demand for water.

Domestic wastewater is divided into two categories, domestic wastewater and domestic sewage. Domestic wastewater mainly refers to domestic water with a high degree of pollution, while domestic sewage refers to domestic drainage water used by people, which has a lower degree of pollution than domestic wastewater. Building, residential and community domestic drainage water as a source of raw water system, according to whether domestic wastewater and domestic sewage in a set of collector, and divided into a combined flow of raw water system and diversion of raw water system, the latter using two sets of pipelines, respectively, collector. Shunt type system raw water quality is better, lower treatment costs, users are easy to accept, but due to the addition of a set of diversion of drainage pipes, the space occupied inside the building is also larger, the need to increase the investment cost of piping, design, installation is also more complex. Shunt system is usually applied to the centralized compulsion to wash the equipment of office buildings, educational buildings, guest houses, dormitories, public bathrooms, laundries, large hotels, restaurants, etc., for bathing equipment and toilets are arranged separately in the residence, villas, etc., these buildings are easy to do the riser shunt.

The function of the water supply system is to deliver qualified water from the water treatment station of the community to the water points in each place, and to meet the requirements of the water points for water pressure, water quantity and water quality. The water supply system is usually divided into two categories: domestic miscellaneous water supply system and fire-fighting water supply system. In the water supply method, there are various ways such as direct water supply and pressurized water supply.

Miscellaneous domestic water supply system for residential buildings, large public buildings and residential neighborhoods flushing toilets, washing vehicles, watering roads, watering flowers and trees to provide the required water. The system is usually composed of water supply pipes, valves, meters, pressurization and storage equipment within the district and building. Inside the building water supply pipe connecting the building water equipment and water connection pipe between the pipeline to ensure that the indoor toilet flushing and cleaning water, water supply pipe inside the building, including water trunk, water risers and water branch pipe, the same corrosion-resistant pressurized pipe.

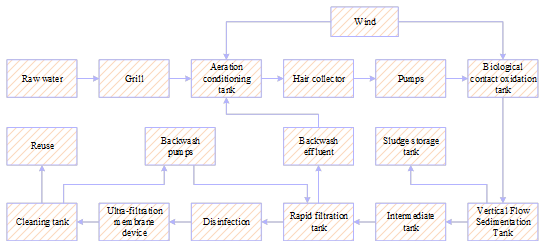

Considering the applicability of green intelligent buildings to the water reuse system, this paper chooses to use an independent water reuse system, and the following is the process of constructing the water reuse system of the green intelligent building constructed in this paper. Figure 1 shows the technical process using membrane-biological contact oxidation (MBR), the design principle of this water reuse process system is: to use low energy consumption, low investment, technologically mature process routes, and minimize the cost. Considering the overall planning of the green intelligent building, the water reuse system is designed near the green belt so as to facilitate the planning and construction of the system pipeline.

Grid is a kind of equipment to retain coarse dirt in sewage wastewater, the role is to retain and filter larger dirt to avoid subsequent pipeline clogging.

Width of grating trough \(\left(B/m\right)\) is \[\label{GrindEQ__1_}\tag{1} B=S(n-1)+bn,\] \[\label{GrindEQ__2_}\tag{2} n=\frac{Q_{\max } \sqrt{\sin \alpha } }{bhv},\] where, \(S\) is the grating width in \(m\), \(n\) is the number of grating gaps in pieces, \(b\) is the grating clearance in \(m\), \(Q_{\max }\) is the maximum design flow rate in \(m^{3} /s\), \(\alpha\) is the grating inclination in \(\mathrm{{}^\circ}\), and \(v\) is the over-grate flow rate in \(m/s\).

The head loss across the grate \(\left(h_{1} /m\right)\) is, \[\label{GrindEQ__3_}\tag{3} h_{1} =h_{0} k,\] \[\label{GrindEQ__4_}\tag{4} h_{0} =\varepsilon \frac{v^{2} }{2g} \sin \alpha,\] \[\label{GrindEQ__5_}\tag{5} \varepsilon =\beta \left(\frac{s}{b} \right)^{4/3},\] where, \(h_{0}\) for the calculation of head loss unit is \(m\), \(k\) for the head loss increase times, generally used 3 system operation, the original grille on the grille slag will aggravate the head loss. \(g\) for gravity acceleration unit is \(m/s^{2}\), \(\varepsilon\) for the resistance coefficient, grille section has a rectangular, circular, irregular shape, etc., different shapes resistance coefficient size. \(\beta\) for the drag coefficient influence coefficient, generally rectangular for 2.42, round for 1.79.

Flow out of the raster groove direction out of the total height of the canal \((H/m)\) is, \[\label{GrindEQ__6_}\tag{6} H=h+h_{1} +h_{2}/\] Total length of the raster \((L/m)\) is, \[\label{GrindEQ__7_}\tag{7} L=l_{1} +l_{2}.\]

When the system is running, the water volume is large and small, uneven, the regulating pool plays the role of regulating the water volume to ensure that the equipment can operate normally, not because of the overflow of the water volume is large, and not because of the water volume is small and idle. The regulating pool is designed as a steel concrete structure, and the purpose of aeration is to prevent the water body from odor.

Adjustment pool volume is calculated according to the water volume change curve, in this case, according to 45% of the daily treatment capacity. Its effective volume is: \[\label{GrindEQ__8_}\tag{8} \begin{array}{rcl} {V} & {=} & {0.45Q_{\max } }. \end{array}\]

Because of the collection of sewage containing bath drainage, so the sewage pump suction pipe should be set on the hair filter, filter net using corrosion-resistant materials, 3mm aperture, the effective water area should be connected to the pipe 2.0 \(\mathrm{\sim}\) 4.0 times, the project uses 200mm diameter connecting pipe, so the effective water area of the filter net \(s\) can be designed for: \[\label{GrindEQ__9_}\tag{9} \begin{array}{rcl} {s} & {=} & {3s_{1} }. {} \end{array}\]

Contact oxidation tank is the core equipment of the water treatment system, is the place to purify sewage, consists of pool body, filler, water distribution device and aeration device. Wastewater flows into the contact oxidation tank and filler contact, under the action of biofilm to achieve the purpose of purification.

Effective volume of oxidation pool \(\left(V/m^{3} \right)\) is, \[\label{GrindEQ__10_}\tag{10} V=\frac{Q_{\max } \left(L_{a} -L_{1} \right)}{M},\] where, \(Q_{\max }\) is the maximum daily effluent volume in units of \(m^{3}\), \(L_{a}\) is the influent concentration in units of \(mg/L\), \(L_{1}\) is the effluent concentration in units of \(mg/L\), and \(M\) is the volumetric loading in units of \(gBOD_{5} /\left(m^{3} \cdot d\right)\).

The area of the contact oxidation tank is \(\left({F\mathord{\left/ {\vphantom {F m^{2} }} \right. } m^{2} } \right)\) is, \[\label{GrindEQ__11_}\tag{11} \begin{array}{rcl} {F} & {=} & {\frac{V}{H} } . \end{array}\]

Calibrate the contact time is, \[\label{GrindEQ__12_}\tag{12} t=\frac{nfH}{Q_{\max } }.\]

Total height of the oxidation pond \(\left(H_{0} \right)\) is, \[\label{GrindEQ__13_}\tag{13} H_{0} =H+h_{1} +h_{2} +(m-1)h_{3} +h_{4}.\]

Vertical flow sedimentation tank is often used as a small sewage treatment plant sludge discharge equipment, wastewater in the vertical flow sedimentation tank in the vertical flow, through the center pipe in the middle of the pool from the bottom to the top into the sedimentation tank, the pipe is equipped with an umbrella-shaped baffle at the bottom of the outlet, the direction of the water flow in the sedimentation tank and the direction of the particles of the opposite direction of sedimentation, particles ultimately sunk to the bottom of the pool, and the clarified water from the top of the pool overflows. Vertical flow sedimentation tank is composed of three parts, tank wall, center pipe and mud discharge pipe.

Center pipe area \(f/\left(m^{2} \right)\) is, \[\label{GrindEQ__14_}\tag{14} f=\frac{q_{\max } }{v_{0} }.\]

Center tube pipe diameter is, \[\label{GrindEQ__15_}\tag{15} d_{0} =\sqrt{\frac{4f}{\pi } }.\]

Sedimentation tank diameter \(D(m)\) is, \[\label{GrindEQ__16_}\tag{16} D=\sqrt{\frac{4(A+f)}{\pi } }.\]

The effective water depth of the settling tank \(\left(h_{1} \right)\), then \[\label{GrindEQ__17_}\tag{17} h_{1} =vt.\]

The volume of the circular truncated cone of the settling tank is recorded as \(V_{1} \left(m^{3} \right)\), and the height of the cone is, \[\label{GrindEQ__18_}\tag{18} h_{2} =\left(D/2-d^{1/2} \right)\tan \alpha,\]

From there, \[\label{GrindEQ__19_}\tag{19} V_{1} =\frac{\pi h_{5} }{3} \left(R^{2} +r^{2} +Rr\right).\]

Total height of settling tank \(H(m)\) is, \[\label{GrindEQ__20_}\tag{20} H=h_{1} +h_{2} +h{'}.\]

The purpose of a rapid filtration tank is to provide rapid filtration of treated water to retain some of the bacteria, microorganisms, suspended solids, etc. in the water.

Filter tank area is, \[\label{GrindEQ__21_}\tag{21} F=\frac{Q}{vT}.\]

Filter pool height, total height of the filter pool by the support layer, filter media layer, filter media on the depth of water, super high, filter plate height. The height of the support layer of this project \(H_{1}\) to take \(0.25m\), the filter media layer using quartz sand layer, the height of \(H_{2}\) to take \(0.6m\), the depth of water on the filter media \(H_{3}\) to take \(0.3m\), \(H_{4}\) to take \(0.25m\), the height of the filter plate \(H_{5}\) to take \(0.1m\), then the total height of the filter tank is, \[\label{GrindEQ__22_}\tag{22} \begin{array}{rcl} {H} & {=} & {H_{1} +H_{2} +H_{3} +H_{4} +H_{5} } . \end{array}\]

Then the formula for the number of centralized ultrafiltration membrane modules \(n\) is, \[\label{GrindEQ__23_}\tag{23} N=\frac{Q_{\max } }{F}.\]

The clean water tank is the equipment for temporary storage of treated water, and its volume is determined according to the change curve of water consumption. This water project is a 24-hour continuous operation project, its volume can be calculated according to 25% of the daily water volume, i.e., \[\label{GrindEQ__24_}\tag{24} V=0.25Q_{\max } =27.5m^{3}.\]

The method used to construct a water reuse system for green intelligent buildings. After the construction is completed, this study analyzes two aspects of the water reuse system, which are social and economic benefits.

In order to test the quality of the water in the water, the structures and equipment used in this paper are as follows,

(1) Oxygen membrane bioreactor

Biochemical tank and membrane tank with integrated design, the pool contains a large number of activated sludge, can effectively remove COD, BOD, phosphorus and other pollution indicators. OCEANPOWER independently developed hollow fiber membrane module, PE material, pore size of 0.5 \(\mu\)m. sludge return pump is installed in the pool, the position is far away from the membrane module, to minimize the dissolved oxygen in the reflux mixture, and the reflux mixture is transported by pipeline to the bottom of the conditioning tank. The aerobic membrane bioreactor is designed with HRT of 7 hours and volume of 40m\(^{3}\).

(2) Ultraviolet sterilization system

Adopt ultraviolet sterilizer for sterilization and disinfection, equipment material 304SS, manual cleaning.

(3) Equipment room

Ground design, covers an area of about 20, canopy cover, mainly placed suction pumps, blowers, electronic control systems, ultraviolet sterilizer and other equipment.

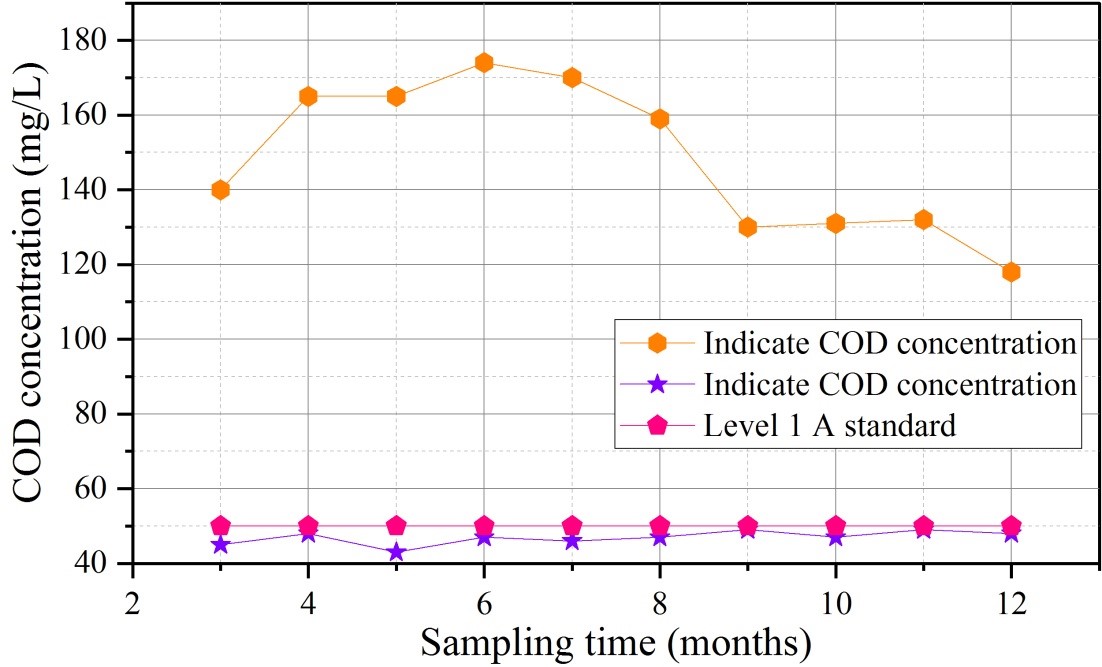

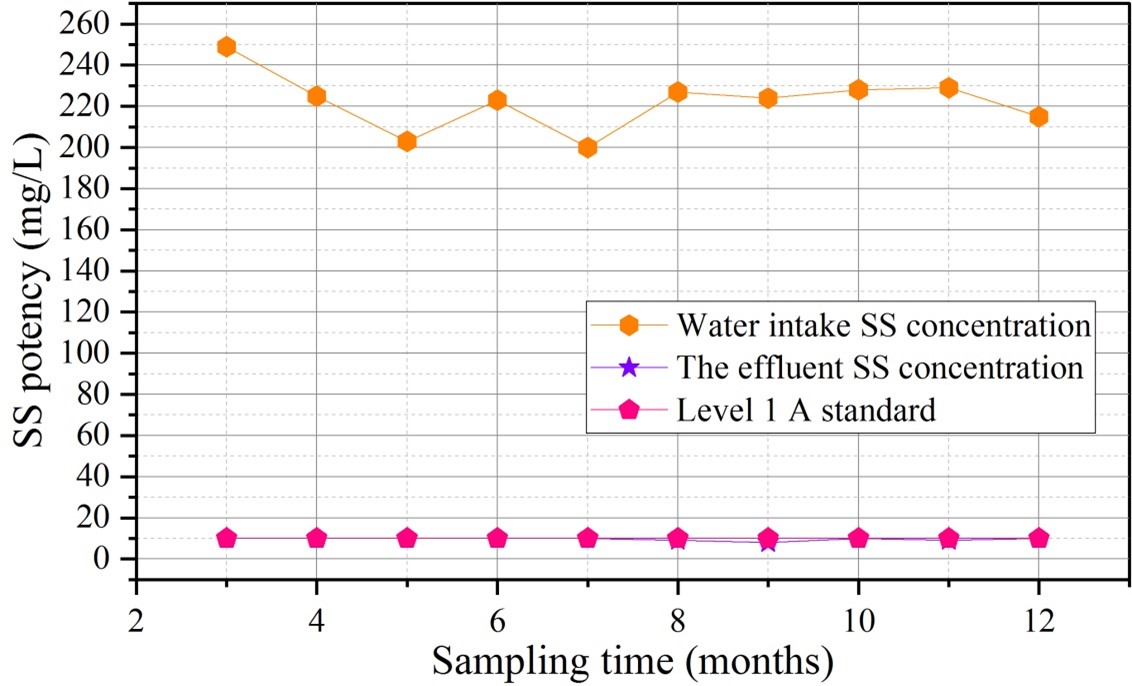

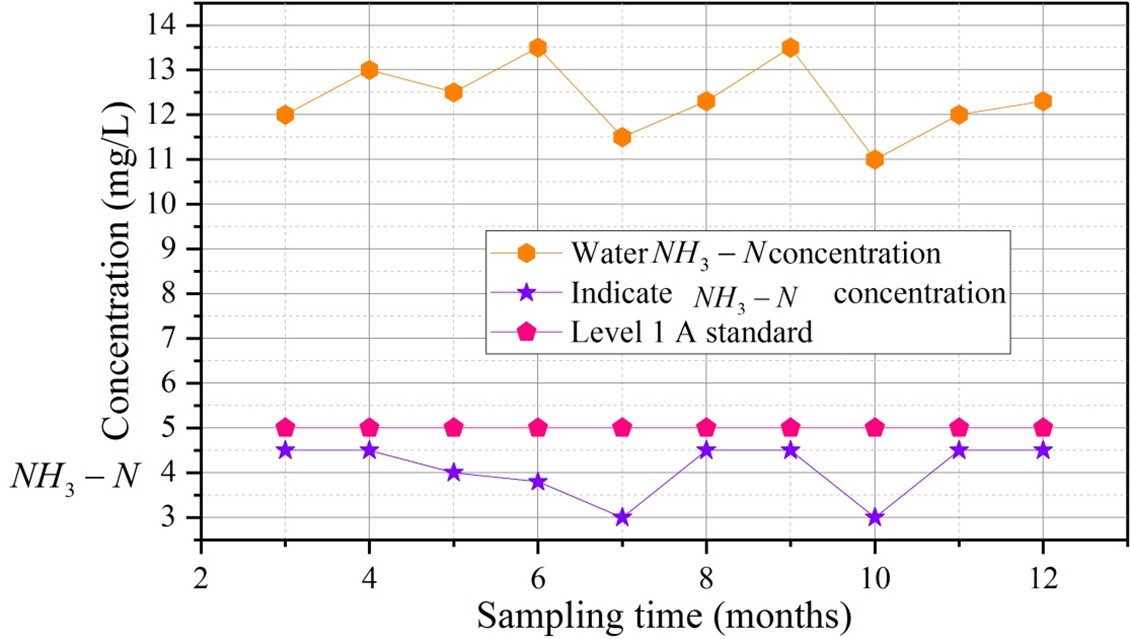

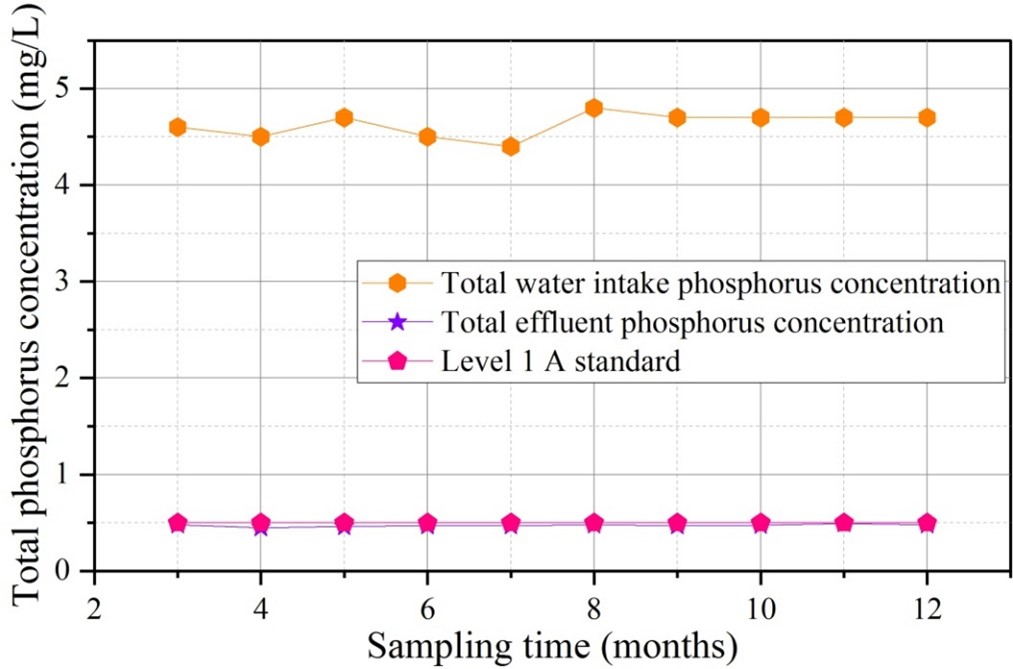

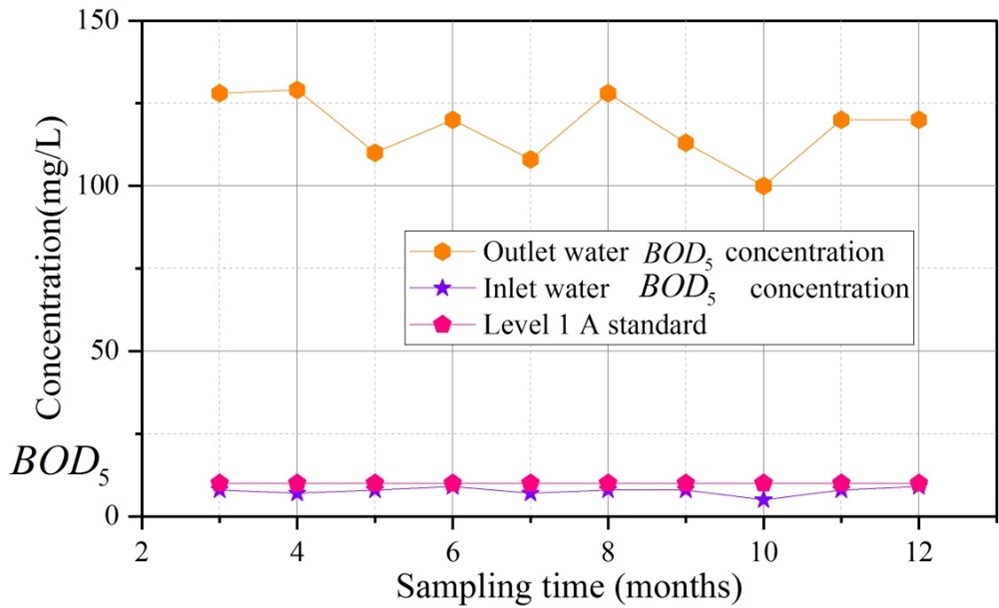

Figure 2 shows the inlet and outlet water quality monitoring of the water reuse system of the green intelligent building, and the water quality monitoring of the water reuse system designed in this paper was carried out for a period of 10 months, and Figures 2 (a)-(e) are the five key monitoring substances in the water quality, respectively, for COD, SS, \(NH_{3-N}\), TP, and \(BOD_{5}\).

In Figure 2 (a), the COD concentration of 20 times of influent monitoring varied from 118 to 174 mg/L, with an average value of 148.4 mg/L. The highest and lowest concentrations occurred in June and December, respectively. After treatment by the water reuse system, the COD concentration in the 20 times of effluent monitoring was reduced to below 50mg/L, basically around 46mg/L, which meets the standard of reuse water.

In Figure 2 (b), the SS concentration in 20 times of influent monitoring varied within the range of 200mg/L to 249mg/L, and the average value of 10 months was about 222.3mg/L. The highest concentration was 249mg/L monitored in March, and the lowest concentration was 200mg/L monitored in July. After the treatment by the water reuse system, the SS concentration of the 20 times of effluent monitoring basically stayed between 8\(\mathrm{\sim}\)10mg/L, and the effluent was in compliance with the standard of reuse water. After the water reuse system treatment, the SS concentration of 20 times of effluent monitoring basically stays between 8\(\mathrm{\sim}\)10mg/L, and the SS concentration of effluent water is less than the standard 10mg/L, which meets the standard of water reuse. The remaining three substance concentrations are similar to those mentioned above, and the water reuse system of the green intelligent building designed in this paper complies with the standard of water treatment, and it can be put into use.

The daily amount of treated and purified water in the water system of the green intelligent building has some changes, and the whole is floating up and down around the design scale, which is at the level of dynamic equilibrium.

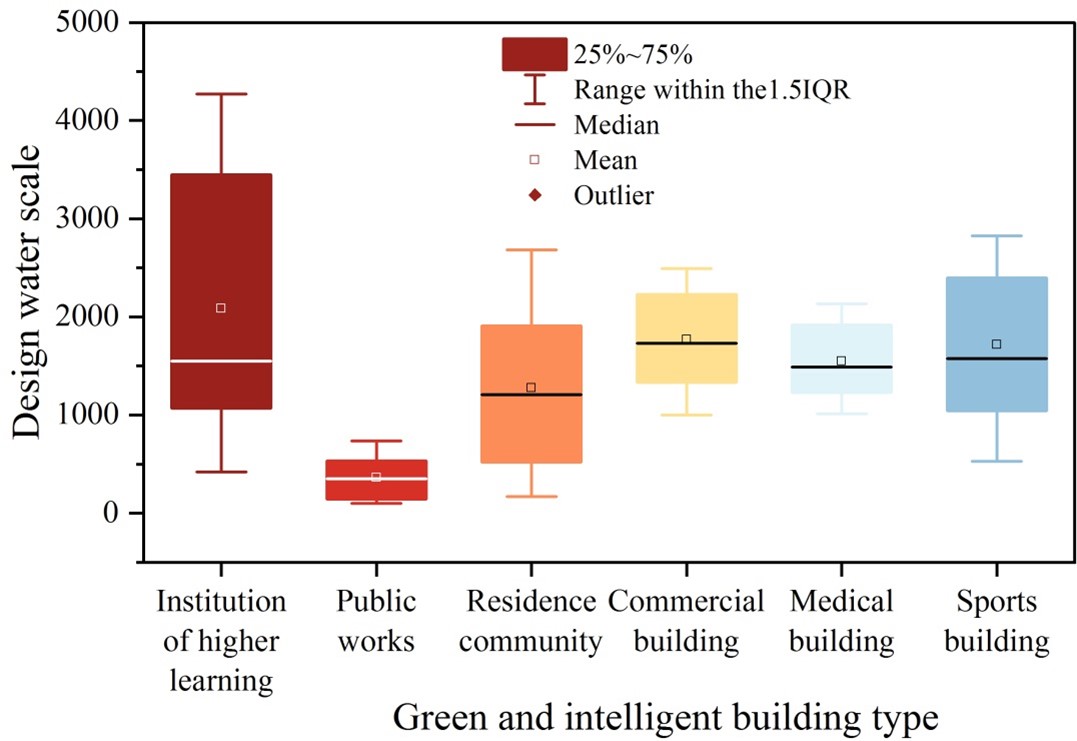

Figure 3 indicates that this paper for three different scenarios of green intelligent building design of water reuse system design water volume scale and the actual scale of water production, The filled part of the box represents the 25%-75% confidence interval range with an outlier coefficient of 15, the horizontal line in the box represents the median, the hollow point is the mean, and the solid point is the outlier. Figure 3 (a) is the design water volume scale. From the vertical coordinate in the box diagram, it can be visualized that the average value of the designed water volume of the water reuse project in the smart building of universities is significantly higher than that of the other two types of buildings, as high as 2087.7297m\(^{3}\)/d, while the distribution of the designed water volume is more dispersed and overall high. Compared with the university, the design water volume distribution of public building water project is concentrated, 25%\(\mathrm{\sim}\)75% of the project size are concentrated between 230\(\mathrm{\sim}\)510m\(^{3}\)/d, the treatment capacity is low, the average value is only 362.5675m\(^{3}\)/d. In the residential area, the design scale reaches the highest to 2683.26 m\(^{3}\)/d, except for the residential water project, the design water volume distribution is uniform, the average value is 1277.6703m\(^{3}\)/d.

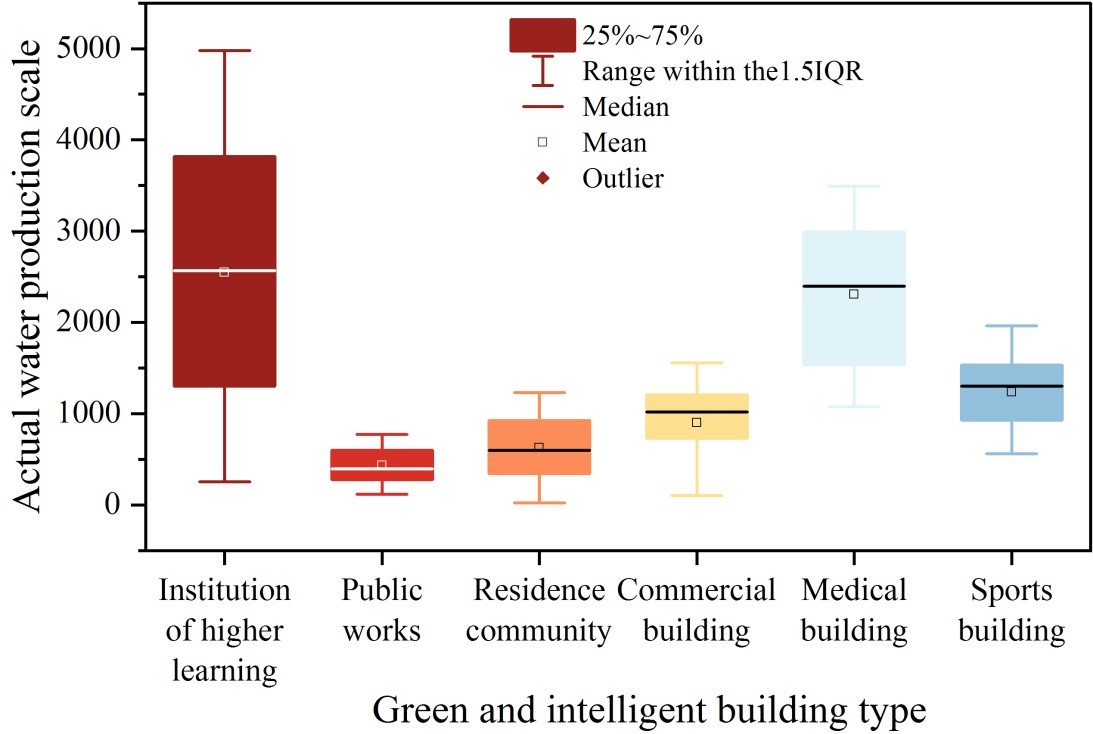

Figure 3 (b) shows the actual water production scale of three types of green intelligent building supporting water projects. As can be seen from the figure, the mean values of the actual water production scale of the three types of green intelligent building water projects are as follows: higher education (2548.8816m\(^{3}\)/d) \(\mathrm{>}\) residential district (628.4478m\(^{3}\)/d) \(\mathrm{>}\) public building (431.625m\(^{3}\)/d), the scale of the university water project is running well, and the production of water is stable, and the small-scale hotels, buildings, etc., the actual operation of the water is low, 1/2 about the actual water production of public building water projects is 264\(\mathrm{\sim}\)600m\(^{3}\)/d.

Table 1 shows the calculation of annual carbon emissions from water reuse. The process of water reuse has two parts: carbon generation and carbon reduction. Among them, carbon is generated from water treatment and distribution, and the reduction of carbon emissions is caused by the reduction of water input, internal consumption, and wastewater (rainwater) discharge in 3 parts. The changes in carbon emissions due to water reuse are shown in the table. It can be seen that: although the treatment and transmission and distribution of water will produce carbon emissions of 4000.4279kg \(CO_{2}\), the carbon reduction due to water saving also reaches 2749.459kg \(CO_{2}\), which indicates that although water reuse in general will increase a certain amount of carbon emissions, but the increment is small.

| Class | Carbon structure | Project | $$E_i $$ | $$C_i $$ | $$VCE/(kgCO_{2} )$$ | |

| Carbon production link | Internal consumption | Water treatment | 2515.01m$$^3$$ | 0.82kg/$$CO_2 / m^3 $$ | 2062.3082 | 4000.4279 |

| Water distribution | 1545.55kW.h | 1.254 kg/ $$CO_2 /$$(kWh) | 1938.1197 | |||

| Carbon reduction link | Water input | Water supply treatment and distribution | 2314.65 m$$^3$$ | 0.4522kg/ $$CO_2 / m^3 $$ | 1046.6847 | 2749.459 |

| Internal consumption | Waste waste (rain) water discharge | Sewage disposal | 2314.65 m$$^3$$ | 0.1752kg$$CO_2 / m^3 $$ | 405.5267 | |

| Secondary water supply | 942.65 kWh | 1.315 kg/ $$CO_2 /$$(kWh) | 1239.5848 | |||

| Disinfection by ultraviolet light | 43.85 kWh | 1.315 kg/ $$CO_2 /$$(kWh) | 57.6628 | |||

| Annual changes in carbon emissions | +1250.9689 | |||||

(1) Cycle Cost Projections

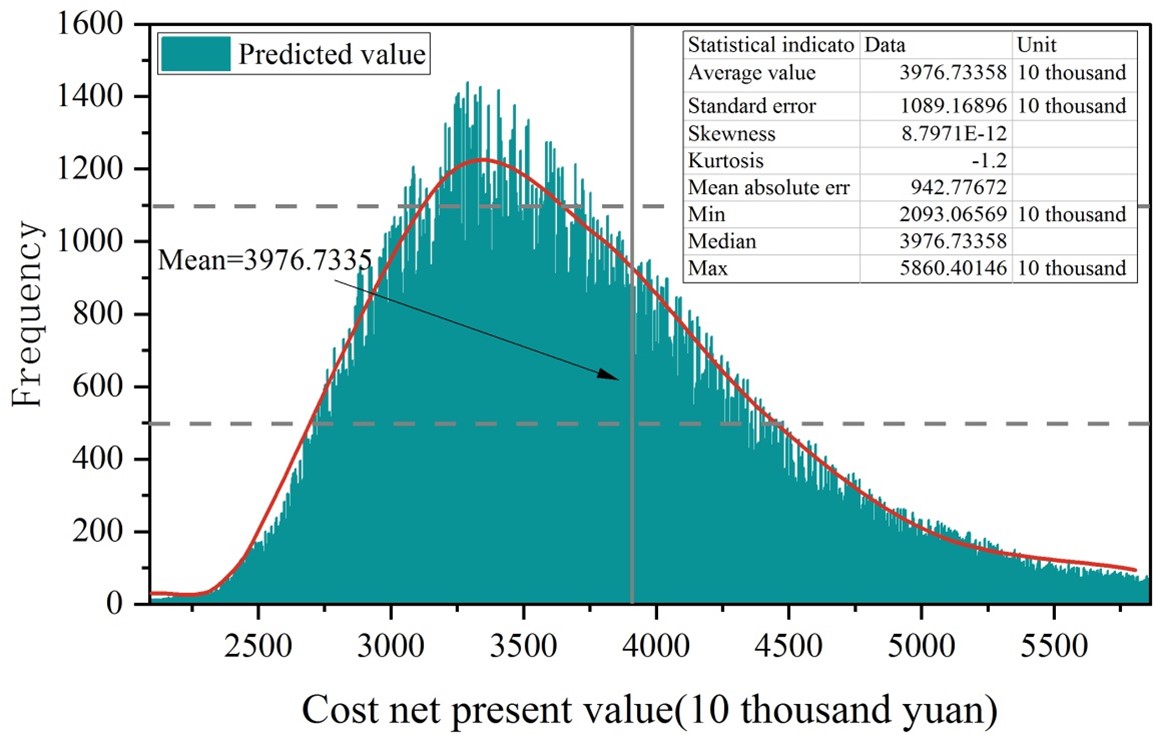

In order to ensure the simulation accuracy and reduce the chance error, high-frequency simulation times (1000 times) are used for simulation, while the accuracy of the prediction results is ensured at the confidence level of 0.95. Starting the simulation program, the simulation of 1000 groups of full-life-cycle cost sample tests of water reuse systems in green intelligent buildings can be obtained, and Figure 4 shows the distribution of the data and the related statistical indexes. And the indicators were analyzed with descriptive statistics, and Table 2 shows the results of descriptive analysis. It can be visualized that the distribution of full life cycle cost samples of water reuse projects in green intelligent buildings in this study, its mean value is about 39,767,335,000 yuan, 1000 groups of sample data obey the lognormal distribution, and the best fit, combined with the data in the table, we can see that the skewness of -8.7971 \(\mathrm{\times}\) 10\(\mathrm{\wedge}\)-12 \(\mathrm{<}\) 0 distribution of the overall negative skewness, the kurtosis of -1.2 \(\mathrm{<}\) 3 so there are fewer extreme data, it can be seen that Acting on the sample value of the whole life cycle cost of water reuse system does not produce large variability.

| Statistical indicators | Data | Unit |

|---|---|---|

| Average value | 3976.73358 | 10 thousand yuan |

| Standard error | 1089.16896 | 10 thousand yuan |

| Skewness | 8.80E-12 | |

| Kurtosis | -1.2 | |

| Mean absolute error | 942.77672 | |

| Min | 2093.06569 | 10 thousand yuan |

| Median | 3976.73358 | |

| Max | 5860.40146 | 10 thousand yuan |

(2) Sensitivity analysis

Figure 3 shows the sensitivity of the cost prediction of the water project in the green intelligent building designed in this paper, with the rank correlation coefficients reflecting the influence of each variable on the cost prediction, Cs, Co, to, m, Ca, ta, Ue, t, Qt, l, r represent the net residuals, overhaul cost, overhaul frequency, maintenance, approximate consumption cost growth rate, replacement cost, tons of water energy cost, time years, and the actual size of the water production, respectively, management cost growth rate, and discount rate. Negative values indicate that changes in the variables are negatively correlated with the predicted outcomes, while positive values indicate the opposite. From the figure, it can be seen that in absolute value, the influence of each variable on the whole life cycle cost prediction of water reuse system in green intelligent buildings is as follows: discount rate (0.698) \(\mathrm{>}\) management cost growth rate (0.614) \(\mathrm{>}\) actual water production scale (0.275) \(\mathrm{>}\) time period (0.234) \(\mathrm{>}\) energy cost per ton of water )(0.178) \(\mathrm{>}\) replacement frequency (0.097) \(\mathrm{>}\) replacement cost (0.02) \(\mathrm{>}\) replacement frequency (0.097). Replacement cost (0.02), and the remaining variables are too small to be compared. Based on the analysis of the cost prediction benefits, it can be seen that the variables will have a large degree of positive pull effect on the economic benefits of the water project in green intelligent buildings.

(1) Analysis of Investment Indicators for Project Water Volume

Figure 6 for different types of buildings in the water project water volume investment indicators, the overall average value of 3772.122 yuan / (m\(^{3}\) / d). By the vertical coordinates of the box plot can be visualized, the initial construction of public water projects need to invest the most money, more than the other two types of buildings in the sum of the average value of the water volume indicators, as high as 6678.6572 yuan / (m\(^{3}\)/d), and the extreme difference is large, for 10439.83 yuan / (m\(^{3}\)/d). Higher education and residential water project water volume investment index mean value is similar, divided into 2339.6625 yuan / (m\(^{3}\) / d) and 2298.0463 yuan / (m\(^{3}\) / d), and the overall water volume index are lower than 4000 yuan / (m\(^{3}\) / d), the degree of distribution is concentrated, with a certain investment economy.

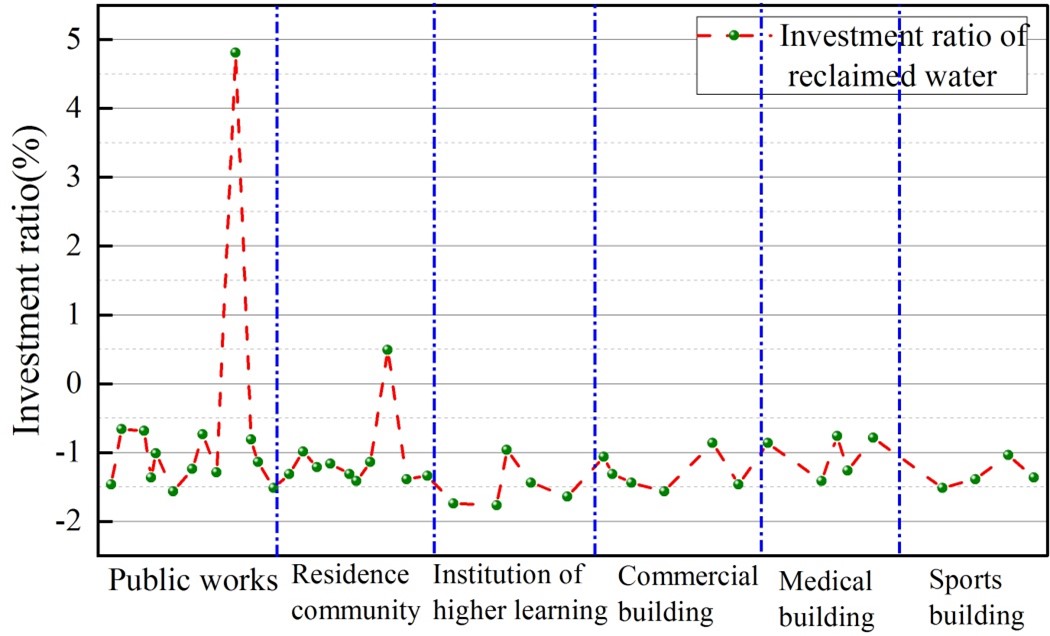

(2) Analysis of the percentage of the cost of the main building

Figure 7 for the water project investment in the main building cost of the proportion, as can be seen from the figure, the water project investment accounted for very little, the overall fluctuations in the vicinity of 0.62%, will not bring too much extra economic burden to the main building cost, which the public buildings and residential neighborhoods using water reuse system due to the low cost of the main building, resulting in a high proportion of 4.91% and 1.75%, the rest of them are less than 1.00%.

Comprehensive above, the water reuse system designed in this paper in the construction of water projects in universities cost-effective, the current development of water in the building is in a slow stage, the early years of production of water reuse pilot operation effectiveness is also high and low immediately see, with the accumulation of engineering experience, process technology to pull out high, supply and demand market is becoming more and more stable, the construction of the project requires the investment of funds also fell.

(3) Static payback period analysis

In order to build a green intelligent building water reuse system in higher education as an example, the total investment in the construction of the system is 4,356,500 yuan, and according to the system’s annual operation of 9 months to consider, then the cost of water production is calculated as follows:

The annual operating cost of the water reuse portion is taken as 4% of the investment, i.e., $174,300, and the annual management and maintenance cost is taken as 2% of the investment, i.e., $87,130. Assuming that the life of the water treatment system is 10 years, calculate the NPV \(NPV\) and NAV \(NAV\) based on economics: \[\label{GrindEQ__25_}\tag{25} NPV=PVB-PVC,\] where \(PVB\) is the present value of the total benefits of the water reuse system and \(PVC\) is the present value of the total costs of the water reuse system. \[\label{GrindEQ__26_}\tag{26} NAV=NPV\frac{i(1+i)^{n} }{(1+i)^{n} -1} (i=7\% ,n=10).\] Then \(NAV=435.65\times 0.1424=62.04\).

It is estimated that the annual reclaimed water output of the system is 321,018.46 tons, so the cost of reclaimed water treatment is 1.933 yuan/t. According to the survey, the tap water price in the region in 2015 was 3.65 yuan/t (including sewage charges), and the average price of tap water was 4.38 yuan/t if the annual growth rate of tap water in 2015\(\mathrm{\sim}\)2024 was 4%. Therefore, the annual water cost saving is 785,600 yuan, and the water cost is 7.856 million yuan in 10 years. Table 3 shows the static payback period analysis, from which it can be seen that the cumulative net cash flow is positive from the 9th year, so the static payback period of the university’s green intelligent building reclaimed water reuse system project is 9 years. At the same time, a random survey was conducted on the acceptance of water by users, which was categorized into three grades according to the acceptance of users, with non-acceptance as grade I, and the percentage of residents in City A was 12.45%. General acceptance is rank II, and the percentage of residents is 15.75%. Full acceptance is rank III, with 71.8% of residents.

| A particular year(Year) | Cost(10 thousand yuan) | Beneficial result(10 thousand yuan) | Net cash flow(10 thousand yuan) | Accumulative total of net cash flow(10 thousand yuan) |

| 0 | 435.65 | 0 | -435.65 | -435.65 |

| 1 | 26.14 | 78.56 | 52.42 | -383.23 |

| 2 | 26.14 | 78.56 | 52.42 | -330.81 |

| 3 | 26.14 | 78.56 | 52.42 | -278.39 |

| 4 | 26.14 | 78.56 | 52.42 | -225.97 |

| 5 | 26.14 | 78.56 | 52.42 | -173.55 |

| 6 | 26.14 | 78.56 | 52.42 | -121.13 |

| 7 | 26.14 | 78.56 | 52.42 | -68.71 |

| 8 | 26.14 | 78.56 | 52.42 | -16.29 |

| 9 | 26.14 | 78.56 | 52.42 | 36.13 |

| 10 | 26.14 | 78.56 | 52.42 | 88.55 |

(1) Limited number of users surveyed

In this paper, the acceptance of users in A city has been investigated in more detail, but the number of areas selected in A city is limited, which results in the acceptance of the entire water reuse system users have great limitations in the research work. At the same time, many cities and towns do not pay enough attention to the management of documents and data, the storage and management of documents is more chaotic, which causes certain difficulties in data collection, and the data obtained is not comprehensive and accurate enough, and some of them come from the oral statement of the citizens, which is deviated from the actual situation. The accuracy of the data, not representative enough, if you increase the scope and intensity of the research, a city user acceptance status will be more in-depth study.

(2) Water treatment methods should be combined with the actual situation of specific places, determined through experiments.

In this paper, the choice of water treatment method is based on the results of previous research, summarize the lessons learned from existing projects, analyze the situation of the use of regional conditions, to determine the appropriate method of water treatment, due to my ability to carry out the relevant experiments, so that the choice of method with a certain degree of subjectivity.

(3) Water reuse research in water-scarce areas should be emphasized

In the context of the continuous development of the new rural construction, the increasing prominence of water shortage and pollution and other contradictions, and water reuse technology in rural areas, in-depth research is very little, the application is almost none. As an effective way to alleviate the water crisis, the application of water reuse should be systematized and scaled up, not only limited to urban residential areas, but also to the construction of new rural areas.

This study demonstrates the significant contribution of the water reuse system in green intelligent buildings in terms of environmental protection and water utilization efficiency through an in-depth study of the system. By adopting membrane bioreactor (MBR) technology, the water reuse system performs well in treating domestic wastewater, in which the COD and SS concentrations are greatly reduced and significantly lower than the national standard for reuse water. Empirical analysis shows that the water reuse systems in different types of buildings have achieved the expected results in actual operation, especially in colleges and universities, where the daily treatment capacity is significant and shows high treatment efficiency.

The economic benefit analysis shows that the payback period of the water reuse system is 9 years, which proves its economic feasibility. The full life cycle cost analysis shows that the average cost of the system is about RMB 39,767,335,000, and this investment is acceptable compared to the long-term water saving and environmental benefits brought by the system. In addition, the operation of the system not only reduces the building’s dependence on traditional water resources, but also significantly reduces the amount of pollutants discharged, which helps to minimize environmental stress.

The water reuse system for green and intelligent buildings plays an important role in improving the efficiency of water resources utilization and promoting the sustainable development of the construction industry. The successful implementation of this system not only provides strong support for energy saving and consumption reduction in the construction industry, but also makes an important contribution to environmental protection.

You Li (1985.5-), female, Han, Huanggang Hubei, master’s degree, engineer, research direction: building water drainage, Guangxi Vocational and Technical College of Mechanical and Electrical Engineering.

Hui Zhong (1982.6-), male, Han, Binyang Guangxi, master’s degree, engineer, research direction: Tobacco logistics management, Laibin Tobacco Monopoly Bureau.

This research was supported by the 2023 one of the achievements of the project “Construction and research of reclaimed water reuse system in green intelligent buildings” (project number: 2023KY1116), which aims to improve the basic scientific research ability of young and middle-aged teachers in Guangxi universities.